Beautiful Work Info About Is Smoothness A Roughness Pyplot 3d Line

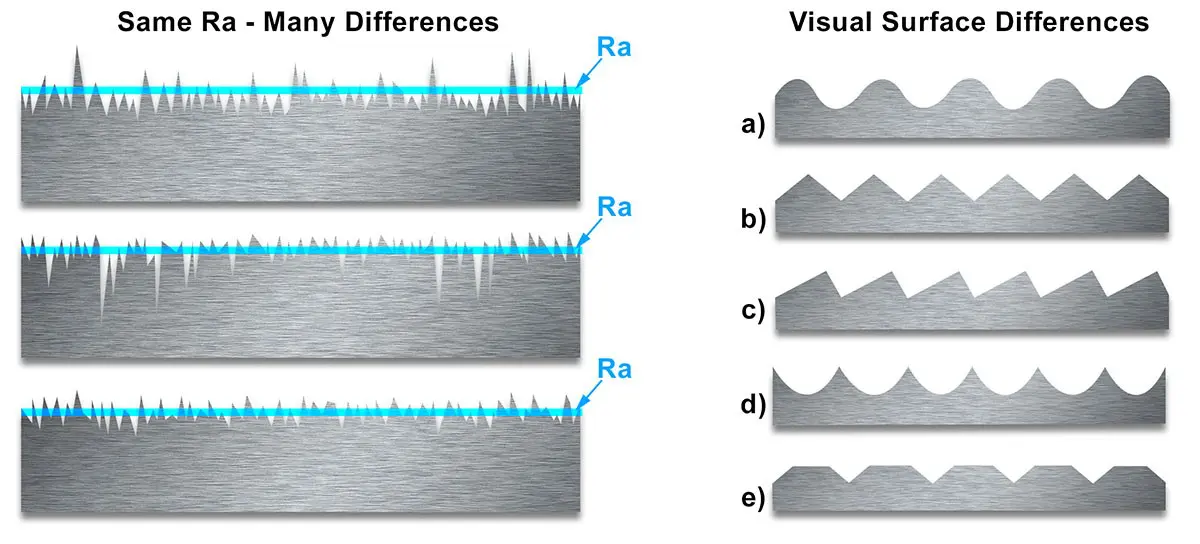

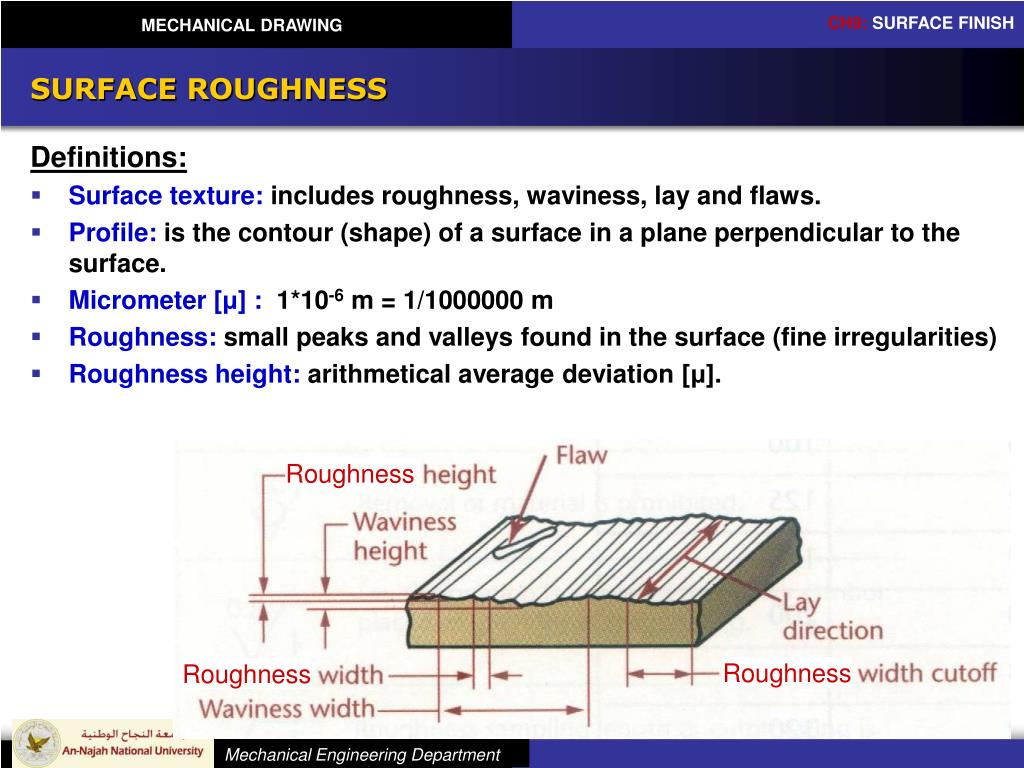

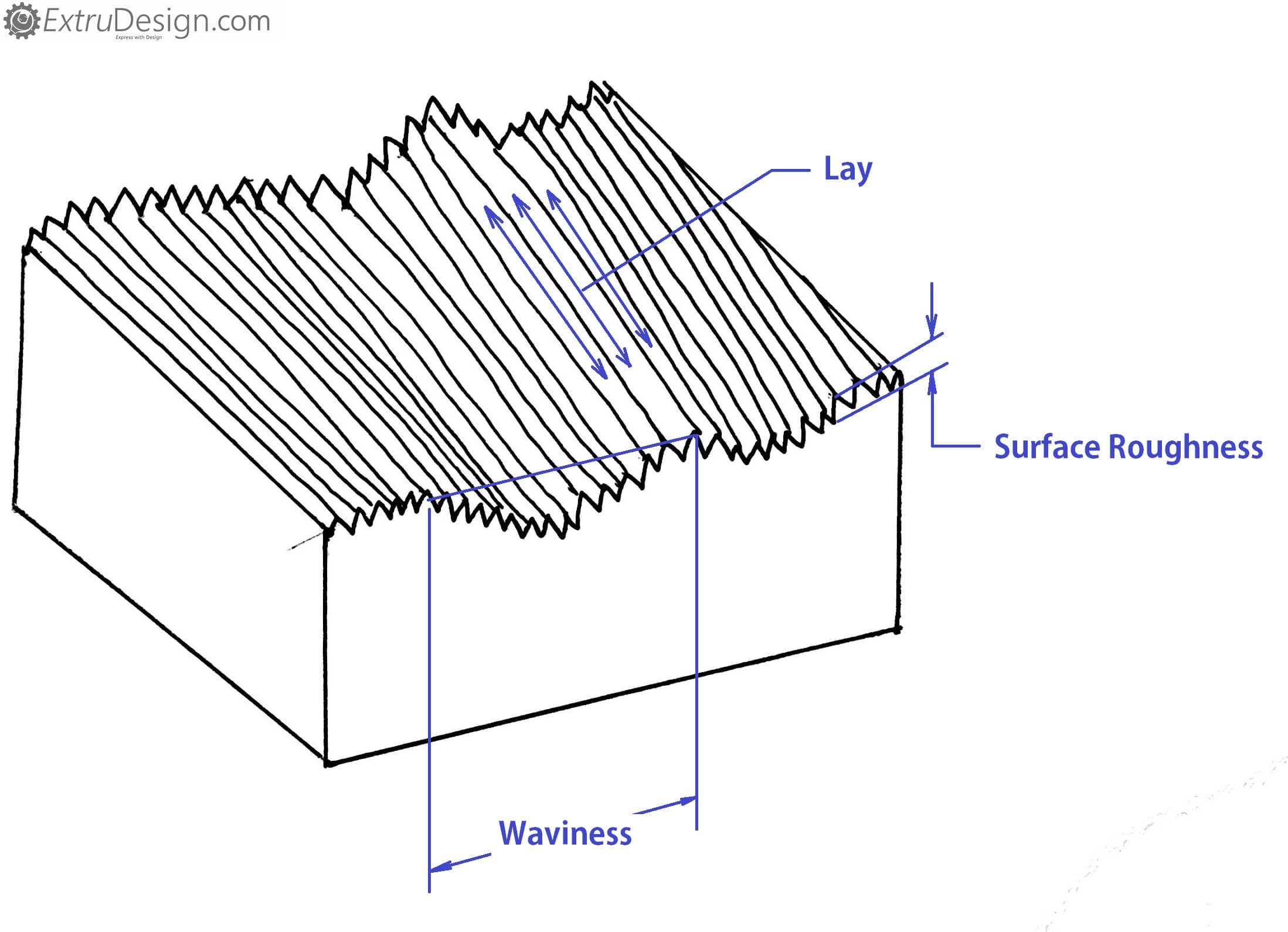

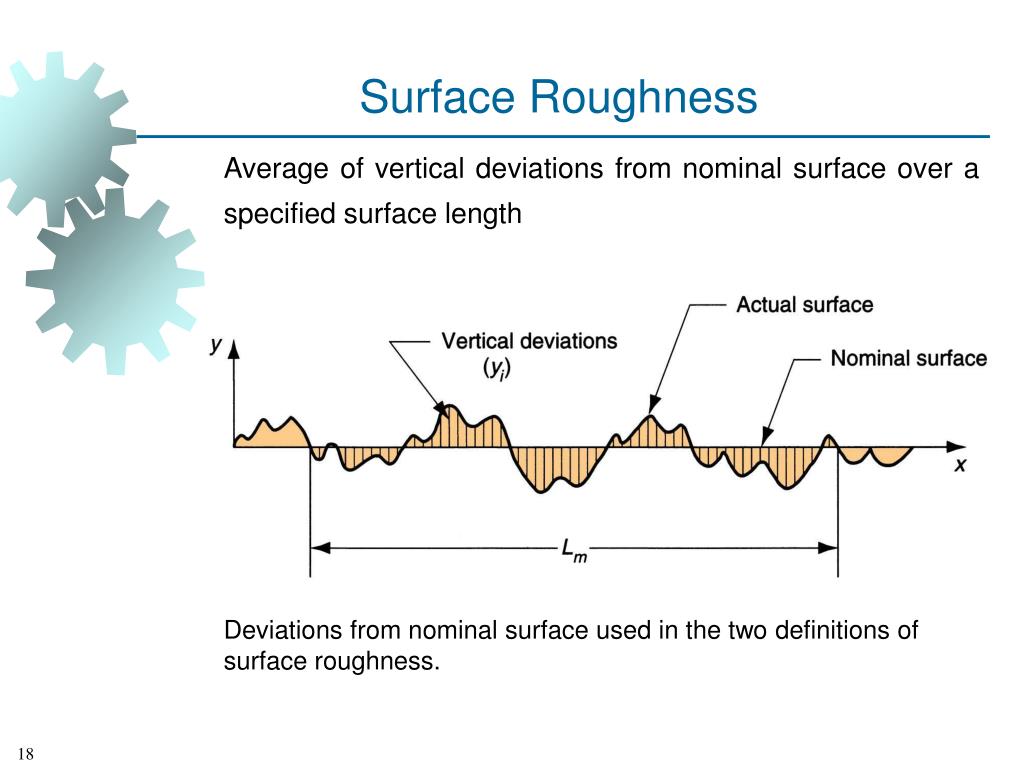

Surface roughness is defined as the shorter frequency of real surfaces relative to the troughs.

Is smoothness a roughness. In tribology, rough surfaces wear faster and have. The condition of being smooth.

The term defines the vertical deviations of a measured surface from its ideal form. If these deviations are large, the surface is rough; Diamonds are used in various industries due to their excellent performance, but the roughness of synthetic diamonds remains a challenge.

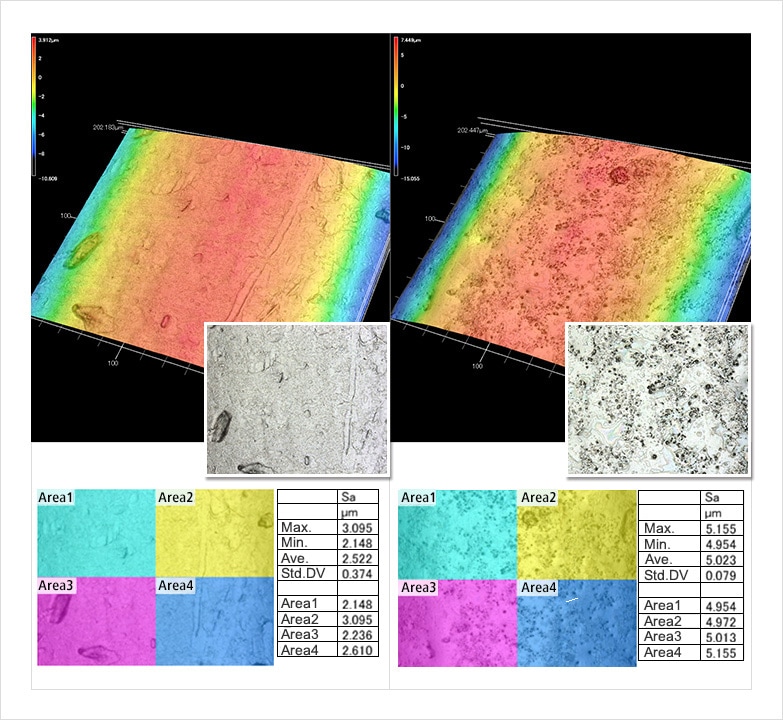

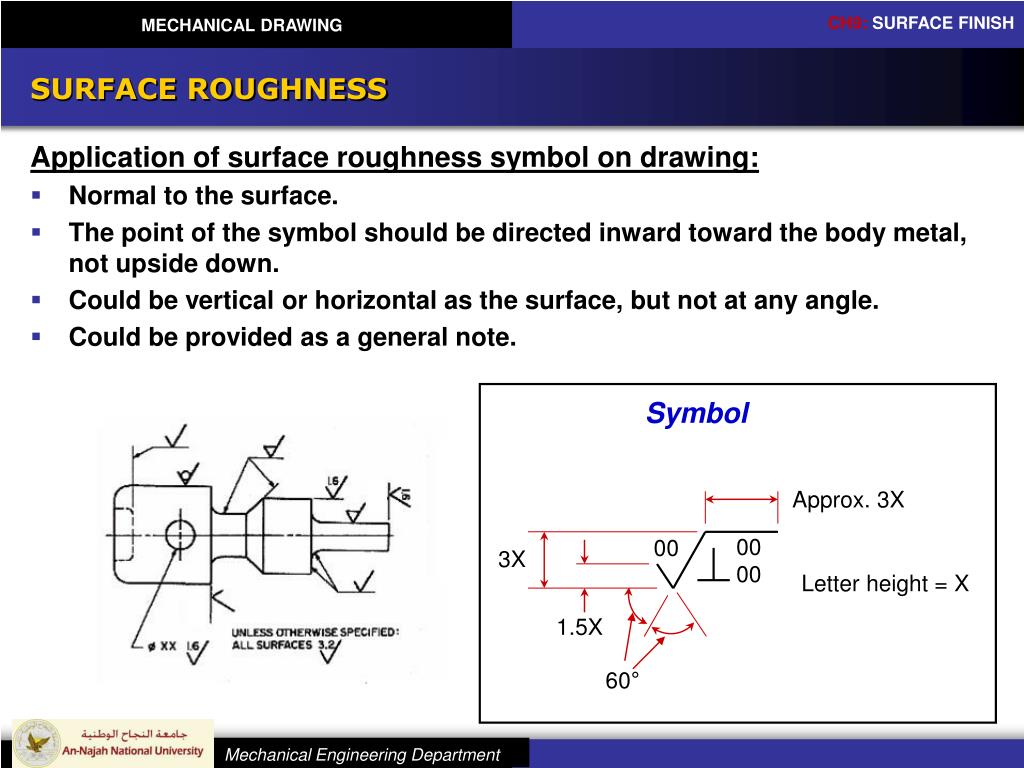

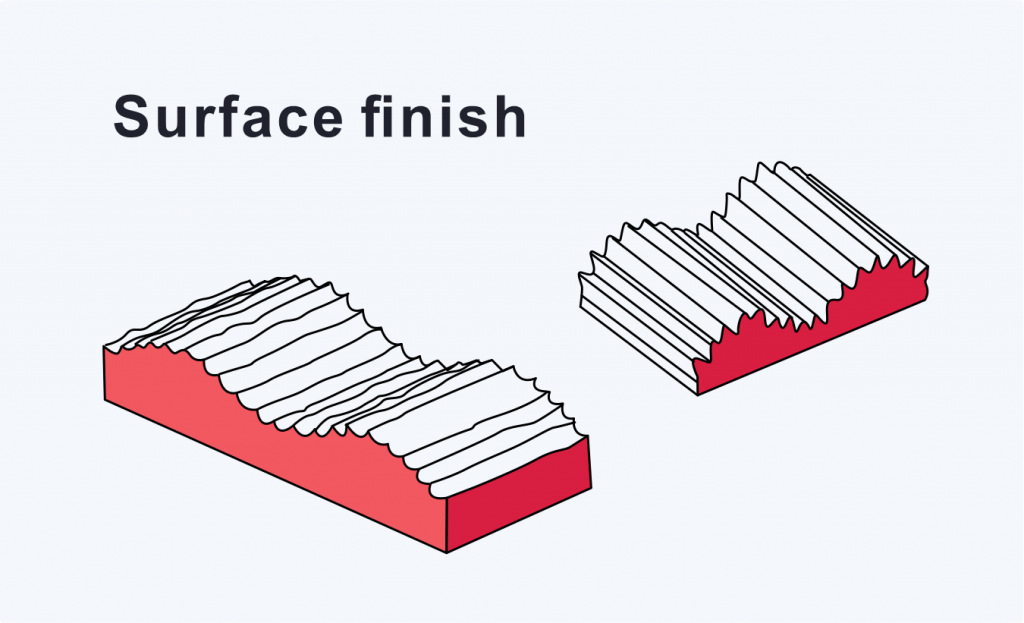

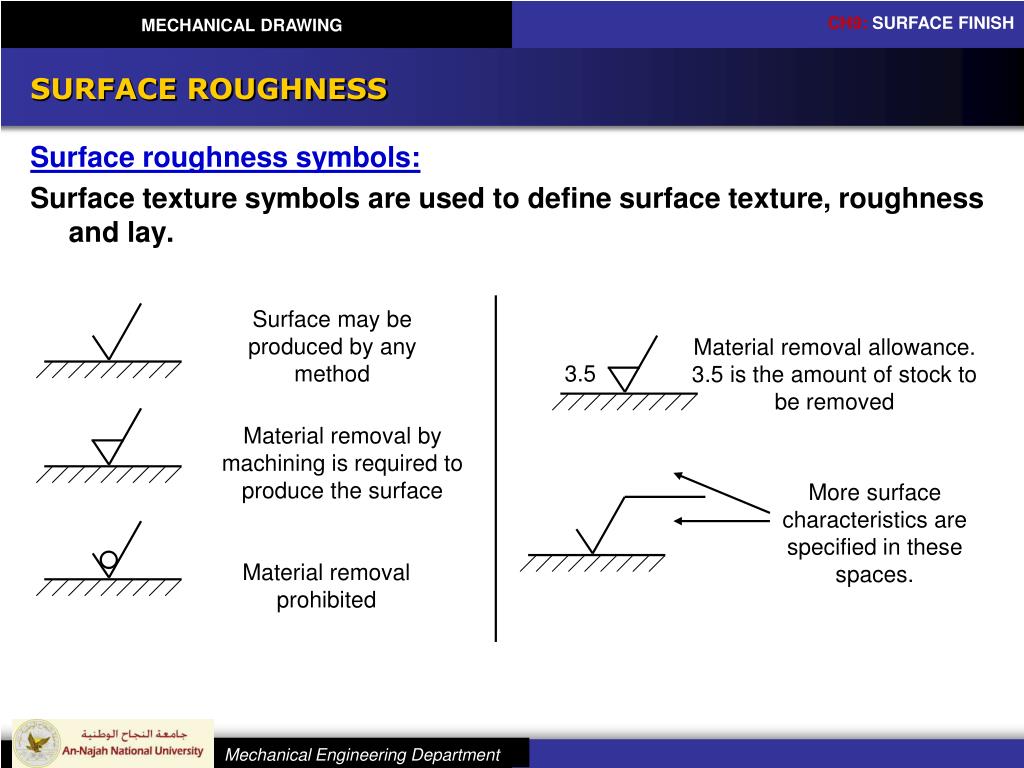

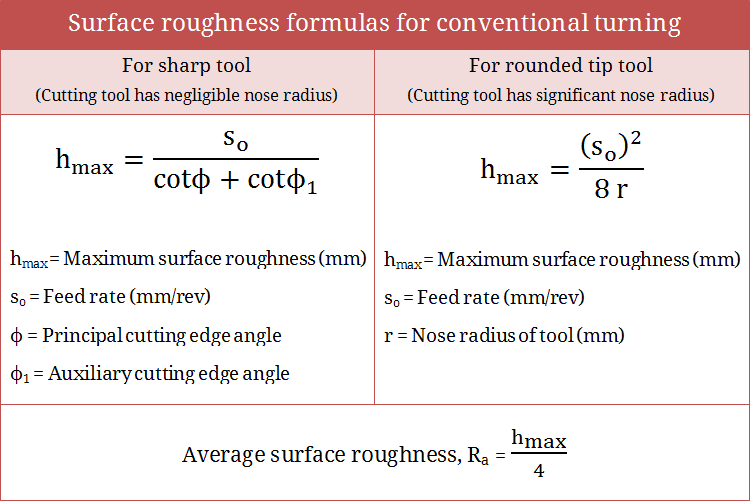

Roughness is the most commonly specified, measured, and calculated aspect of surface finish, and many people use the term “surface finish” to only describe roughness. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a surface's true form. Surface roughness is a calculation of the relative smoothness of a surface’s profile.

If these deviations are substantial, the surface is rough; As described in asme b46.1, rms is the root mean square average of the profile height deviations from the mean line, recorded within the evaluation length. Smoothness is inverted roughness.

The ra surface finish chart shows the arithmetic average of surface heights measured across a surface. When these variations are significant, the surface is considered rough, whereas if they are minimal, the surface is considered smooth. Reveal the rms formula for more insight.

Surface roughness, frequently shortened to roughness, refers to small irregularities in surface geometry. Surface roughness indicates the condition of processed surfaces. If they are minor the surface is smooth.

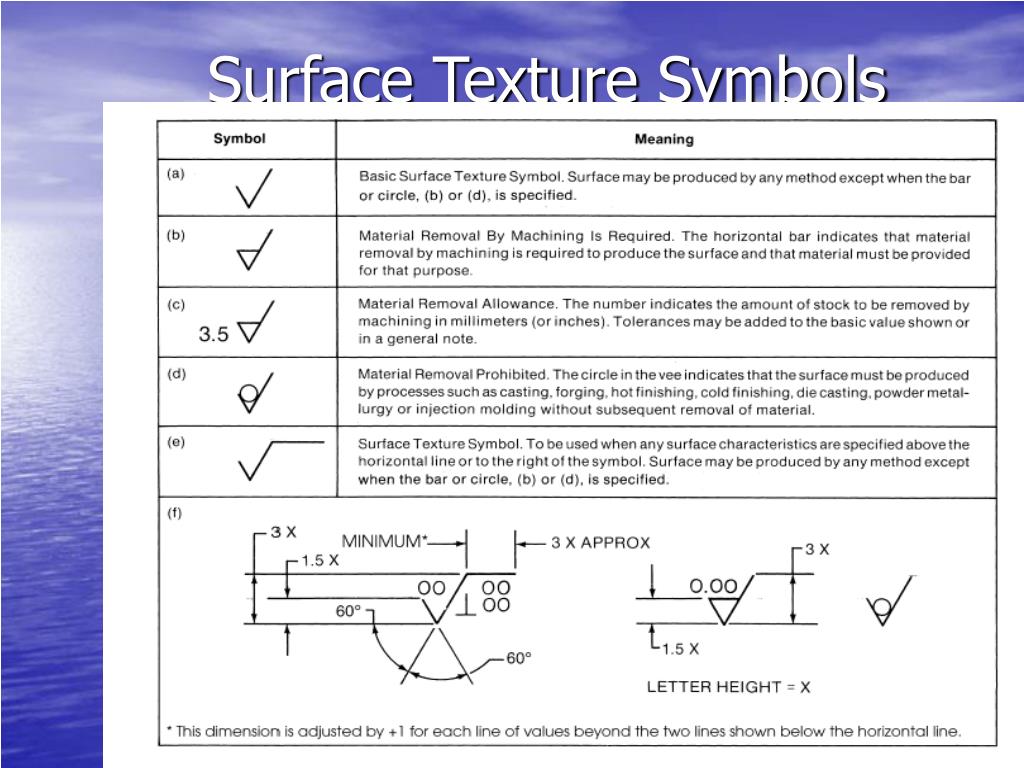

How to measure surface roughness. Surface roughness is a measure of how rough or smooth the surface of a material is. 10 smoothness and surface features.

Surface roughness is one component of describing how the shape of a surface deviates from its ideal form, where higher values correspond to rougher surfaces while lower values indicate the surface is smooth. If you have a smoothness map you can use the invert node to plug it into a roughness input. To be completely smooth, you would use a smooth value of 1.0 or a rough value of 0.0.

Reference guide for laboratory and workshop. The larger the deviation from its true form, the rougher the surface, whilst the smaller the deviation, the smoother the surface. Surface roughness is an excellent predictor of mechanical part performance because irregularities on the surface can produce nucleation sites for fractures or corrosion.

It is typically measured as the differences between peaks and valleys on a given surface. What is surface roughness? The main difference between surface roughness and surface smoothness is that surface roughness is a statistical parameter while surface smoothness is an optical will now talk about surface roughness measurement.